Nexeo plastics and MBA Polymers have signed a long-term distribution agreement for the sale of mechanical recycled, post-Consumer ABS, PS, PC-ABS and PP in the EMEA region. MBA Polymers The contract was signed at the FAKUMA plastic show in Friedrichshafen, Germany.

„We are thrilled that we have found the US-based, global acting,

fast growing partner with a strong customers base. We are extremely happy, we are now offering our range of ABS, PS and PP to even more customers of household appliances and the automotive industry. And I am truly impressed by the super friendly, positive and professional EMEA team, based in Barcelona and headed by Joost d´Hooghe, Vice President Sales EMEA.“

EMEA sales are coordinated by Wolfgang Ganser, COO, who started with MBA Polymers Austria back in 2007. Wolfgang stated: “We will ensure to provide environmental friendly post-consumer ABS, PS and PP with a positive carbon footprint of 4,8 tons CO2 compared to virgin plastics. Our post-consumer resins are made in Europe for Europe. We believe in Nexeos´s innovative 24/7 personalized online order tool and deep understanding of the industry’s needs.

Nexeo Plastics was founded in 1973 and is a leading global thermoplastic resin and compound distributor. Serving over 60 countries with over 20,000 products in various industries, including mobility, healthcare, packaging, wire and cable, and more. The company is known for its extensive network of suppliers and customers, enabling it to offer a diverse portfolio of plastic materials and solutions. Nexeo Plastics aims to serve as a strategic partner to help businesses in different sectors meet their specific plastic needs, whether that involves material selection, technical support, or supply chain management.

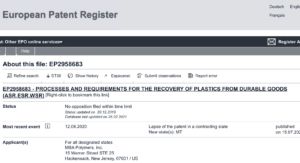

Nexeo Plastics and MBA Polymers signed a long-term distribution agreement