Finding smarter ways to manage plastics beats switching to alternative materials

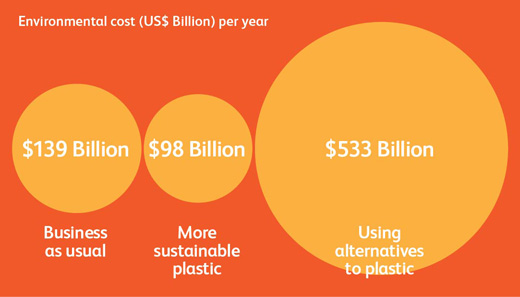

Replacing plastics in consumer goods and packaging with a mix of alternative materials would increase environmental costs almost fourfold from $139bn to $533bn annually, finds a new study by environmental consultancy Trucost.

Using natural capital accounting, Trucost has built on previous plastics reports to conduct an environmental ‘cost comparison’. It looked at the relative costs of using materials such as paper, tin, aluminium and glass compared to plastic (to perform the same function). It also explored whether taking a more sustainable approach to using plastics in consumer goods and packaging might cost the Earth less in the long term.

The rise of plastic

Plastic is an affordable, versatile material with many uses across food packaging, drinking water distribution and medical devices. As demand for plastic has grown, its production has increased from 15m tonnes in 1964 to 311m tonnes in 2014. However, with many plastic products and packaging becoming waste, rather than being reused or transformed into secondary raw materials, plastic pollution has also escalated dramatically. In 2014, Trucost and the Plastic Disclosure Project estimated the cost of plastic pollution to marine ecosystems at $13bn, with the consumer goods sector creating $75bn of environmental impacts through its use of plastic.

Taking a smarter approach to plastics

The report concludes that finding smarter ways to manage the manufacture, transport and use of plastic is more environmentally sustainable than replacing plastic with alternative materials. Using plastics in consumer goods costs the environment 3.8 times less than alternative materials would do, it says. This is because opting for plastic, companies can use a quarter of the volume of material they would need if they were to use alternative materials for the same purpose.

“Our findings run contrary to commonly held perceptions that the environmental impacts of plastic can be best addressed by switching to alternative materials,” says Dr. Richard Mattison, CEO of Trucost. “In fact, our research shows that designing, managing and using plastics more efficiently, in a way that respects circular economy principles, is by far the most environmentally sustainable course of action.”

Importantly, moving to a circular economy could significantly reduce the environmental costs of plastics. In particular, this could be achieved by increasing the recycling of post-consumer plastics to 55% and lowering landfill (to a maximum of 10%). If these targets were to be implemented across Europe and North America, the environmental cost of plastics could be reduced by more than $7.9bn in net terms. Meanwhile, it takes 80% less energy to produce recycled plastic than it does to produce virgin plastic.

“Companies in multiple sectors are lowering their environmental footprints by opting for recycled plastics that offer the same performance characteristics as their virgin plastic equivalents,” says Richard McCombs, CEO of MBA Polymers. “Using advanced technology to recycle plastic also helps to stem the flow of plastic waste to landfills, incinerators and oceans.”

Indeed, capturing plastic waste before it reaches the ocean could cut environment costs to the world’s marine life by over $2.1bn, the report estimates. This would mean improving waste collection and management, particularly in Asia (which it suggests could be responsible for more than 70% of plastic consumer goods waste entering the ocean), and increasingly in Africa. Improving waste collection in Asia could cut the volume of plastic waste entering the oceans annually by more than 45%.

Trucost also identified significant opportunities for plastic to be manufactured and transported more efficiently. The environmental cost of producing plastic for the consumer goods sector stood at more than $60bn in 2015, with the transport of these materials adding a further $53bn. The global plastics industry could deliver $33bn of environmental cost savings, the report suggests, by doubling its use of renewable electricity, using more efficient packaging designs and increasing the fuel efficiency of plastic transportation by 20%.