25

Years of Experience

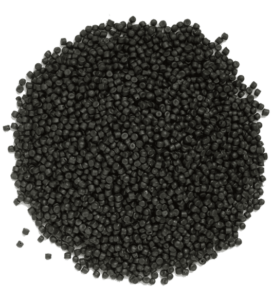

Incorporated 1997 in California, MBA Polymers started with a small-scale production facility in Richmond, Virginia. Fast-forward through a few years of tireless determination and well-placed investments, and MBA Polymers has become the world leader in recycling plastics from end-of-life durable goods such as computers, electronics, appliances, and autos.

Read about the history here.

150,000 t

Processing Capacity

The production units built by MBA Polymers have a total waste processing capacity of above 150,000 t per annum. They’re located in Germany, Austria, China, India and United Kingdom. For a high-end product the waste is processed through 3 different steps.

Read about the manufacturing process here.

200,000 t

CO2 saved per year

Our proprietary process means that a single ton of our product saves approximately 4.8 tons of CO2 compared with the manufacture of virgin materials plastics as well as metals recovered from our feedmaterial), which is a reduction of approximately 90% in CO2 emissions.

47

Patents globally

MBA Polymers’ technology and patents are registered in Australia, Canada, China, Europe and USA. The patents are 100% owned by us, including any improvements made at the plant level. The highly automated polymer separation technology developed and patented by MBA Polymers encompasses over 20 complex separation procedures to facilitate the recovery, purification and monetization of plastics by type and grade at attractive commercial economics.

6

Countries

Located with state-of-the-art production units in Germany, China, India and United Kingdom, MBA Polymers is the leading global supplier of high-value engineered plastics from 100% Post-Consumer Recycled. You also find us in Hong Kong and USA.

Read about the locations here.